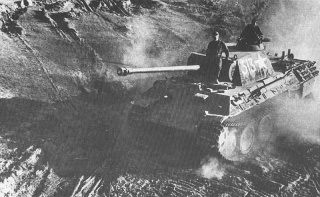

Pz.Kpfw. V Panther

PzV (Stock)

| 1380000 價格 |

| 1200 血量 |

| 44.27 / 45 公斤重量 |

- 車長

| 85/50/40 前/側/後,毫米車身裝甲 |

| 100/45/45 前/側/後,毫米砲塔裝甲 |

| 650 匹馬力引擎功率 |

| 48 公里/小時最高時速 |

| 25 度/秒迴轉速度 |

| 135 標準砲彈殺傷力 |

| 150 毫米標準砲彈穿透力 |

| 5.1 完全裝填的時間 |

| 41 度/秒砲塔迴轉速度 |

| 350 公尺可視範圍 |

| 310 公尺訊號範圍 |

Upon reaching the Panther, you will quickly find that you must change your play style from a close-in brawler to a specialized sniper. At stock, the Panther is armed with the 7.5 cm KwK 42 L/70 which, although a bit low on damage, has sufficient penetration and accuracy for its tier. Its lack of firepower, added to the weak hull sides, make this tank an easy victim in firefights. Once the Panther is fully upgraded and sporting the long, accurate 7.5 cm KwK 45 L/100, it's best to use it as a sniping tank. While it has a low damage totals, and a fairly slow rate of fire for a 75mm gun, it can penetrate virtually all lower tier tanks from any range, as well as higher tier opponents with well aimed shots. The Panther shines as an excellent mobile-sniper, but should never see frontline combat, unless you like seeing your tank in flames.

Compatible Equipment

Compatible Consumables

Player Opinion

Pros and Cons

Pros:

- Its final gun (7,5cm L/100) has good penetration for its tier

- Above average HP (More HP than some tier 7 heavies)

- Weight - ramming is an option as a last resort, though consider your opponent

- 7,5 cm KwK 45 L/100 is one of the most accurate cannons in the game

- Good sloped frontal armor

Cons:

- More unwieldy than other tier 7 mediums

- 7,5cm L/100 has low alpha damage

- Easily targeted and weakly armored ammo rack

- Large silhouette for a medium

- Engine can get damaged or catch fire from hits to the lower glacis

Performance

The Panther is a basically the VK 30.02(M) with more health and a better sniping gun. One thing that changes from the stock panther turret is the shot trap on the VK 30.02(M) turret was blocked with a small plate below the mantle. Coupled with its speed and highly accurate guns it turns into a very deadly sniper. Take on your foes from a distance in the Panther as the more maneuverable American and Soviet mediums are better suited to dog-fighting. The Panther excels as a mobile sniper, especially with the 7,5cm L/100, and should not brawl as it does not quite have the maneuverability to effectively circle heavy tanks. Lower tiers will have trouble penetrating the front of the Panther due to its excellent sloping, and rather large gun mantlet (for both turrets), however it should avoid taking hits from more powerful guns as it is more prone than usual to taking critical hits, especially engine and ammo rack.

Its armor while fairly thin, is surprisingly strong against tier V and some VI guns, so if necessary angle the tank just slightly off to one side, and feel free to bounce many hits. Still, do not rely on the armor, as 85mm is still not enough to reliably stop any 150 or more pen gun regardless of angling, nor is the lower glasis anywhere near the levels of the upper section. Hulldown with the 2nd turret is extremely effective with the 8.8 depression buff, and while its no American tank, it can still hull down and take some hits to its fairly small turret (which is not only bouncy at long range, but has a somewhat trollish mantlet that eats shells, not to mention the schmalturm is quite a small target, making tanks with less accurate guns such as the long 122mm cannon, almost impossible to hit said turret past 400m.

Mobility post 8.8 is not the best but then again, the tank is not a brawler nor a true flanker, meaning for simple relocating or the occasional flanking move, it is adequate. Take note that with the 8.8 "rebalance", the panther has very bad hill climbing characteristics, making speeds of 30 about the maximum that can be achieved going up a medium hill, and speeds as low as 15-20 for steeper hills or cliffs. Still, downhill speed is as high as 60km/hr and flat terrain can see speeds of about 50km/hr if one gives enough time to accelerate to speed.

The things one should avoid while playing any panther (specifically this tank but also applies to the VK 30.02(m) and Panther II) are any type of brawling, trading fire with any tank especially when not at the top of the list, leading the attack, and circling targets like other mediums often do (can be done to a few select tanks but due to sub par turn rate and low speed maneuverability, should be avoided by less experienced players that do not know the exact timing to execute the maneuver). There is one brawling tactic that may work but is again risky and should only be done in self defense; facehugging a enemy can be successful due to the angles increasing and the enemy being denied any good shots at the lower glasis plate. Just be advised what the opponent is and most of all make sure every single of your rounds connects or the great 8.8 patch DPM will not get you out alive (hitting weakspots at point blank range is no problem, and with it even the strongest turrets can be penetrated with careful shooting to cupolas or hatches)

According to many people it is one of if not the best tier VII sniper tank in the entire game, due to the very high penetration (capable of going through many tier IX tanks without APCR), very good accuracy, good DPM (8.8 added a massive boost to rate of fire), and respectable mobility (allowing for decent relocation especially once the enemies get too close). Also as an added benefit this is one tank that perhaps never needs to have a single APCR round loaded at all, due to 198mm of penetration being overkill on anything that is not a tier VIII heavy or a tier IX tank.

Early Research

Your primary objective should be to aquire the 75mm L/100 long barreled gun. While mobility is very important for a medium, the panther, being a sniper tank, really cannot do much without the improved gun, so if only the L/70 is equipped, one may have a very hard time penetrating even many tier VII tanks, let alone tier IX which will occasionally appear.

The second turret can be saved for last due to its only real benefits being a slight increase in view range, and a boost to gun depression. Still, for those that find the panther reasonable without the top engine, it is not a bad upgrade to get right after the L/100.

Historical Info

Panther is the common name of a medium tank fielded by Nazi Germany in World War II. It served from mid-1943 to the end of the European war in 1945. It was intended as a counter to the T-34, and to replace the Panzer III and Panzer IV. While never replacing the latter, it served alongside it as well as the heavier Tiger tanks until the end of the war. The Panther's excellent combination of firepower, mobility, and protection served as a benchmark for other nations' late-war and immediate post-war tank designs, and it is frequently regarded as one of the best tank designs of World War II.

The Panther tank was a compromise of various requirements. While sharing essentially the same engine as the Tiger I tank, it had better frontal armor, better gun penetration, was lighter overall and thus faster, and could handle rough terrain better than the Tiger. The trade-off was weaker side armor. The Panther proved to be deadly in open country and shooting from long range, but vulnerable to close-quarters combat. Also, the 75 mm gun fired a slightly-smaller shell than the Tiger's 88 mm gun, providing less high-explosive firepower against infantry, though it was still quite effective.

The Panther was also far cheaper to produce than the Tiger tanks, and only slightly more expensive than the Panzer IV, as its design came to fruition at the same time that the Reich Ministry of Armament and War Production was making great efforts to increase war production. Key elements of the Panther design, such as its armor, transmission and final drive, were compromises made specifically to improve production rates and address Germany's war shortages, whereas other elements such as its highly compact engine and its complex suspension system remained with their elegant but complicated engineering. The result was that Panther tank production was far higher than what was possible for the Tiger tanks, but not much higher than what had been accomplished with the Panzer IV. At the same time, the simplified final drive became the single major cause of breakdowns of the Panther tank, and was a problem that was never corrected.

The Panther tank arrived in 1943 at a crucial phase in World War II for Germany. Rushed into combat at the Battle of Kursk before its teething problems were corrected, the Panther tank would thereafter only be fighting outnumbered in Germany's steady retreat against the Allies for the remainder of World War II. Its success as a battlefield weapon was thus hampered by Germany's generally declining position in the war, with the loss of airpower protection by the Luftwaffe, the loss of fuel and training space, and the declining quality of tank crews. Nevertheless, the Panther tank demanded respect from the Allies, and its combat capabilities led directly to the introduction of heavier Allied tanks such as the Soviet IS-2 and the American M26 Pershing into the war.

Design

The Panther was a direct response to the Soviet T-34 and KV-1 tanks. First encountered on 23 June 1941, the T-34 outclassed the existing Panzer III and IV. At the insistence of General Heinz Guderian, a special Panzerkommision was dispatched to the Eastern Front to assess the T-34. Among the features of the Soviet tank considered most significant were the sloping armor, which gave much improved shot deflection and also increased the effective armor thickness against penetration, the wide track, which improved mobility over soft ground, and the 76.2 mm gun, which had good armor penetration and fired an effective high explosive round. Daimler-Benz (DB) and Maschinenfabrik Augsburg-Nürnberg AG (MAN) were given the task of designing a new 30- to 35-ton tank, designated VK30.02, by April 1942 (apparently in time to be shown to Hitler for his birthday).

The DB design was a direct homage to the T-34. It resembled the T-34 hull and turret form. DB's design used a leaf spring suspension whereas the T-34 used coil springs. The DB turret was smaller than that of the MAN design and had a smaller turret ring, which was the result of the narrower hull required by the leaf spring suspension which lay outside of hull. The main advantages of the leaf springs over a torsion bar suspension were a lower hull silhouette and a simpler shock damping design. Like the T-34, the DB design had a rear drive sprocket. Unlike the T-34, the DB design had a three-man turret crew: commander, gunner, and loader. But as the planned L/70 75 mm gun was much longer and heavier than the T-34's, mounting it in the Daimler-Benz turret was difficult. Plans to reduce the turret crew to two men to stem this problem were eventually dropped.

The MAN design embodied more conventional German thinking with the transmission and drive sprocket in the front and a turret placed centrally on the hull. It had a gasoline engine and eight torsion-bar suspension axles per side. Because of the torsion bar suspension and the drive shaft running under the turret basket, the MAN Panther was higher and had a wider hull than the DB design. The slightly earlier, Henschel designed Tiger I heavy tank's use of a "slack-track" Christie-style pattern of large road wheels with no return rollers for the upper run of track, and with the main road wheels being overlapping and interleaved in layout, were design concepts broadly repeated with the MAN design for the Panther.

The two designs were reviewed over a period from January through March 1942. Reichminister Todt, and later, his replacement Albert Speer, both recommended the DB design to Hitler because of its several advantages over the initial MAN design. However, at the final submission, MAN improved their design, having learned from the DB proposal, and a review by a special commission appointed by Hitler in May 1942 ended up selecting the MAN design. Hitler approved this decision after reviewing it overnight. One of the principal reasons given for this decision was that the MAN design used an existing turret designed by Rheinmetall-Borsig, while the DB design would have required a brand new turret to be designed and produced, substantially delaying the commencement of production.

Production

The MAN design also had better fording ability, easier gun servicing and higher mobility due to better suspension, wider tracks, and a bigger fuel tank. A mild steel prototype was produced by September 1942 and, after testing at Kummersdorf, was officially accepted. It was put into immediate production. The start of production was delayed, however, mainly because there were too few specialized machine tools needed for the machining of the hull. Finished tanks were produced in December and suffered from reliability problems as a result of this haste. The demand for this tank was so high that the manufacturing was soon expanded beyond MAN to include Daimler-Benz, Maschinenfabrik Niedersachsen-Hannover (MNH) and Henschel & Sohn in Kassel.

The initial production target was 250 tanks per month at MAN. This was increased to 600 per month in January 1943. Despite determined efforts, this figure was never reached due to disruption by Allied bombing, manufacturing bottlenecks, and other difficulties. Production in 1943 averaged 148 per month. In 1944, it averaged 315 a month (3,777 having been built that year), peaking with 380 in July and ending around the end of March 1945, with at least 6,000 built in total. Front-line combat strength peaked on 1 September 1944 at 2,304 tanks, but that same month a record number of 692 tanks were reported lost.

Allied bombing was first directed at the common choke-point for both Panther and Tiger production, the Maybach engine plant. This was bombed the night of 27/28 April 1944 and production was shut down for five months. A second plant had already been planned, the Auto-Union plant at Siegmar, and this came online in May 1944. Targeting of Panther factories began with a bombing raid on the DB plant on 6 August 1944, and again on the night of 23/24 August. MAN was struck on 10 September, 3 October and 19 October 1944, and then again on 3 January and 20/21 February 1945. MNH was not attacked until 14 and 28 March 1945.

In addition to interfering with tank production goals, the bombing forced a steep drop in the production of spare parts. Spare parts as a percentage of tank production dropped from 25–30 percent in 1943, to 8 percent in the fall of 1944. This only compounded the problems with reliability and numbers of operational Panthers, as tanks in the field had to be cannibalized for parts.

Cost

One source has cited the cost of a Panther tank as 117,100 Reichmarks (RM). This compared with 82,500 RM for the StuG III, 96,163 RM for the Panzer III, 103,462 RM for the Panzer IV, and 250,800 RM for the Tiger I. These figures did not include the cost of the armament and radio. In terms of Reichmarks per ton, therefore, the Panther tank was one of the most cost-effective of the German AFV's of World War II. However, these cost figures should be understood in the context of the time period in which the various AFVs were first designed, as the Germans increasingly strove for designs and production methods that would allow for higher production rates, and thus steadily reduced the cost of their AFVs. For example, another source has cited the total cost of the early production Tiger I in 1942–1943 to be as high as 800,000 RM.

The process of streamlining the production of German AFVs first began after Speer became Reichminister in early 1942, and steadily accelerated through 1944; production of the Panther tank thus coincided with this period of increased manufacturing efficiency. German AFV manufacturers at the start of World War II utilized only heavily labor-intensive and costly manufacturing methods unsuitable for the needs of mass production; even with streamlined production methods, Germany never approached the efficiency of Allied manufacturing during World War II.

Engine

The first 250 Panthers were powered by a Maybach HL 210 P30 engine, V-12 gasoline engine which delivered 650 metric hp at 3,000 rpm and had three simple air filters.[19] Starting in May 1943, the Panthers were built using the 700 PS (690 hp, 515 kW)/3000 rpm, 23.1 litre Maybach HL 230 P30 V-12 gasoline engine. The light alloy block used in the HL 210 was replaced by a cast iron block to save aluminum. Two multistage "cyclone" air filters were used to automate some of the dust removal process. In practice the engine power output was reduced due to the use of low quality gasoline. With a capacity of 190 US gallons of fuel, a Panther could operate 60–80 mi (97–130 km) on roads and 40–50 mi (64–80 km) cross country

The HL 230 P30 engine was a very compact design, which kept the space between the cylinder walls to a minimum. The crankshaft was composed of seven discs, each with an outer race of roller bearings, and a crankshaft pin between each disc. To reduce the length of the engine further, by one half a cylinder diameter, the two banks of 6 cylinders of the V-12 were not offset - the center points of the connecting rods of each cylinder pair in the "V" where they joined the crankshaft pin were thus at the same spot rather than offset; to accommodate this arrangement, one connecting rod in the pair of cylinders was forked and fit around the other "solid" connecting rod at the crankshaft pin. (A more typical "V" engine would have had offset cylinder banks and each pair of connecting rods would have fit simply side by side on the crankshaft pin). This compact arrangement with the connecting rods was the source of considerable teething problems early on. Blown head gaskets were another problem, which was corrected with improved seals in September 1943. Improved bearings were introduced in November 1943 to replace the faulty ones that had failed frequently. An engine governor was also added in November 1943 that reduced the maximum engine speed to 2500 rpm. An eighth crankshaft bearing was added beginning in January 1944 to help reduce motor failures.

The engine compartment space was designed to be watertight so that the Panther could be submerged and cross waterways. The result was that the engine compartment was poorly ventilated and prone to overheating. The fuel connectors in the early models were non-insulated, leading to leakage of fuel fumes into the engine compartment. This led to many engine fires in the early Panthers. Additional ventilation was added to draw off these gasses, which mitigated but did not completely solve the problem of engine fires. Other measures taken to reduce this problem included improving the coolant circulation inside the motor and adding a reinforced membrane spring to the fuel pump. The Panther had a solid firewall separating the engine compartment and the fighting compartment to keep engine fires from spreading.

The engine became more reliable over time. A French assessment of their stock of captured Panthers in 1947 concluded that the engine had an average life of 1,000 km (620 mi) and maximum life of 1,500 km (930 mi).

Suspension

The suspension consisted of front drive sprockets, rear idlers and eight double-interleaved rubber-rimmed steel road wheels on each side, suspended on a dual torsion bar suspension. The dual torsion bar system, designed by Professor Ernst Lehr, allowed for a wide travel stroke and rapid oscillations with high reliability, thus allowing for relatively high speed travel by this heavy tank over undulating terrain. However, the extra space required for the bars running across the length of the bottom of the hull, below the turret basket, increased the overall height of the tank and also prevented an escape hatch in the hull bottom. When damaged by mines, the torsion bars often required a welding torch for removal.

The Panther's suspension was complicated to manufacture and the interleaved system made replacing inner road wheels time consuming. The interleaved wheels also had a tendency to become clogged with mud, rocks and ice, and could freeze solid overnight in the harsh winter weather of the Eastern Front. Shell damage could also cause the road wheels to jam together and become extremely difficult to separate. Interleaved wheels had long been standard on all German half-tracks. The extra wheels did provide better flotation and stability, and also provided more armor protection for the thin hull sides than smaller wheels or non-interleaved wheel systems, but the complexity meant that no other country ever adopted this design for their tanks. In September 1944, and again in March/April 1945, M.A.N. built a limited number of Panther tanks with steel roadwheels originally designed for the Tiger II and late series Tiger I tanks. Steel roadwheels were introduced from chassis number 121052 due to raw material constraints.

From November 1944 through February 1945, a conversion process began to use sleeve bearings in the Panther tank, as there was a shortage of ball bearings. The sleeve bearings were primarily used in the running gear; plans were made also to convert the transmission to sleeve bearings, but were not carried out as production of Panther tanks came to an end.

Steering and transmission

Steering was accomplished through a seven-speed AK 7-200 synchromesh gearbox, designed by Zahnradfabrik Friedrichshafen, and a MAN single radius steering system, operated by steering levers. Each gear had a fixed radius of turning, ranging from five meters for 1st gear up to 80 meters for 7th gear. The driver was expected to judge the sharpness of a turn ahead of time and shift into the appropriate gear to turn the tank. The driver could also engage the brakes on one side to force a sharper turn. This manual steering was a much simplified design, compared to the more sophisticated dual-radius hydraulically controlled steering system of the Tiger tanks.

The AK 7-200 transmission was also capable of pivot turns, but this method of turning could accelerate failures of the final drive.

Throughout its career, the weakest parts were its final drive units. The problems were from a combination of factors. The original MAN proposal had called for the Panther to have an epicyclic gearing (hollow spur) system in the final drive, similar to that used in the Tiger I. However, Germany at the time suffered from a shortage of gear-cutting machine tools and, unlike the Tiger tanks, the Panther was intended to be produced in large numbers. To achieve the goal of higher production rates, numerous simplifications were made to the design and its manufacture. This process was aggressively pushed forward, sometimes against the wishes of designers and army officers, by the Chief Director of Armament and War Production, Karl-Otto Saur (who worked under, and later succeeded, Reichminister Speer). Consequently, the final drive was changed to a double spur system. Although much simpler to produce, the double spur gears had inherently higher internal impact and stress loads, making them prone to failure under the high torque requirements of the heavy Panther tank. Furthermore, high quality steel intended for double spur system was not available for mass production, and was replaced by 37MnSi5 tempered steel, which was unsuitable for high-stress gear. In contrast, both the Tiger II and the US M4 Sherman tank had double helical (herringbone gears) in their final drives, a system that reduced internal stress loads and was less complex than epicyclic gears.

Compounding these problems was the fact that the final drive's housing and gear mountings were too weak because of the type of steel used and/or the tight space allotted for the final drive. The final gear mountings deformed easily under the high torque and stress loads, pushing the gears out of alignment and resulting in failure. Due to the weakness of the final drives their average fatigue life was only 150 km. In Normandy, about half of the abandoned Panthers were found by the French to have broken final drives. However, at least the final gear housing was eventually replaced with stronger one, while final gear problem was never solved.

Plans were made to replace the final drive, either with a version of the original epicyclic gears planned by MAN, or with the final drive of the Tiger II. These plans were intertwined with the planning for the Panther II, which never came to fruition because Panzer Commission deemed that temporary drop in production of Panther due to merger of Tiger II and Panther II was unacceptable. It was estimated that building the epicyclic gear final drive would have required 2.2 times more machining work than double spur gears, and this would have affected manufacturing output.

Most of the shortcomings were considered acceptable once design flaws were rectified. Due to the mechanical unreliability of final gear Panther must be driven with care, a characteristic shared with the Tiger tanks as well as Jagdtigers. Long road marches would result in a significant number of losses due to breakdowns, and so the German Army had to ship the tanks by rail as close to the battlefield as possible.

Mobility

Lieutenant Colonel Wilson M. Hawkins of the 2nd AD wrote the following comparing the US M4 Sherman and German Panther in a report to Allied headquarters:

"It has been claimed that our tank is the more maneuverable. In recent tests we put a captured German Mark V [Panther] against all models of our own. The German tank was the faster, both across country and on the highway and could make sharper turns. It was also the better hill climber"

This was backed up in an interview with Technical Sergeant Willard D. May of the 2nd AD who commented:

"I have taken instructions on the Mark V [Panther] and have found, first, it is easily as maneuverable as the Sherman; second the flotation exceeds that of the Sherman"

Staff Sergeant and Tank Platoon Sergeant Charles A Carden completes the comparison in his report:

"The Mark V [Panther] and IV [Tiger] in my opinion have more maneuverability and certainly more flotation. I have seen in many cases where the Mark V and VI tanks could maneuver nicely over ground where the M4 would bog down. On one occasion I saw at least 10 Royal Tigers [Tiger B] make a counter attack against us over ground that for us was nearly impassible"

Armor

Initial production Panthers had a face-hardened glacis plate (the main front hull armor piece), but as armor-piercing capped rounds became the standard in all armies (thus defeating the benefits of face-hardening, which caused uncapped rounds to shatter), this requirement was deleted on March 30, 1943. By August 1943, Panthers were being built only with a homogeneous steel glacis plate. The front hull had 80 mm of armor sloped back at 55 degrees from the vertical, welded but also interlocked for strength. The combination of a steep slope and thick armor meant that few Allied or Soviet weapons could penetrate this part of the tank.

The armor for the side hull and superstructure (the side sponsons) was much thinner (40–50 mm). The thinner side armor was necessary to keep the overall weight within reasonable bounds, but it made the Panther vulnerable to attacks from the side by most Allied and Soviet tank and anti-tank guns. German tactical doctrine for the use of the Panther thus emphasized the importance of flank protection. Five millimeter thick skirt armor, known as Schürzen, intended to provide protection for the lower side hull from Soviet anti-tank rifle fire was fitted on the hull side. Zimmerit coating against magnetic mines started to be applied at the factory on late Ausf D models beginning in September 1943; an order for field units to apply Zimmerit to older versions of the Panther was issued in November 1943. In September 1944, orders to stop all application of Zimmerit were issued, based on rumors that hits on the Zimmerit had caused vehicle fires.

Panther crews were aware of the weak side armor and made unauthorized augmentations by hanging track links or spare roadwheels onto the turret and/or the hull sides. The rear hull top armor was only 16 mm thick, and had two radiator fans and four air intake louvres over the engine compartment that were vulnerable to strafing by aircraft.

As the war progressed, Germany was forced to reduce or no longer use certain critical alloy materials in the production of armor plate, such as nickel, tungsten, molybdenum, and manganese; this did result in lower impact resistance levels compared to earlier armor. Manganese from mines in the Ukraine ceased when the German Army lost control of this territory in February 1944. Allied bombers struck the Knabe mine in Norway and stopped a key source of molybdenum; other supplies from Finland and Japan were also cut off. The loss of molybdenum, and its replacement with other substitutes to maintain hardness, as well as a general loss of quality control resulted in an increased brittleness in German armor plate, which developed a tendency to fracture when struck with a shell. Testing by U.S. Army officers in August 1944 in Isigny, France showed catastrophic cracking of the armor plate on two out of three Panthers examined.

Armament

The main gun was a 7.5 cm Rheinmetall-Borsig KwK 42 (L/70) with semi-automatic shell ejection and a supply of 79 rounds (82 on Ausf. G). The main gun used three different types of ammunition: APCBC-HE (Pzgr. 39/42), HE (Sprgr. 42) and APCR (Pzgr. 40/42), the last of which was usually in short supply. While it was of only average caliber for its time, the Panther's gun was one of the most powerful tank guns of World War II, due to the large propellant charge and the long barrel, which gave it a very high muzzle velocity and excellent armor-piercing qualities. The flat trajectory also made hitting targets much easier, since accuracy was less sensitive to range. The Panther's 75 mm gun had more penetrating power than the main gun of the Tiger I heavy tank, the 8.8 cm KwK 36 L/56, although the larger 88 mm projectile might inflict more damage if it did penetrate.

The tank typically had two MG 34 machine guns of a specific version designed for use in armored combat vehicles featuring an armored barrel sleeve. An MG 34 machine gun was located co-axially with the main gun on the gun mantlet; an identical MG 34 was located on the glacis plate and fired by the radio operator. Initial Ausf. D and early Ausf. A models used a "letterbox" flap opening, through which the machine gun was fired.[58] In later Ausf A and all Ausf G models (starting in late November-early December 1943), a ball mount in the glacis plate with a K.Z.F.2 machine gun sight was installed for the hull machine gun.

Turret

The front of the turret was a curved 100 mm thick cast armor mantlet. Its transverse-cylindrical shape meant that it was more likely to deflect shells, but the lower section created a shot trap. If a non-penetrating hit bounced downwards off its lower section, it could penetrate the thin forward hull roof armor, and plunge down into the front hull compartment. Penetrations of this nature could have catastrophic results, since the compartment housed the driver and radio operator sitting along both sides of the massive gearbox and steering unit; more importantly, four magazines containing main gun ammunition were located between the driver/radio operator seats and the turret, directly underneath the gun mantlet when the turret was facing forward.

From September 1944, a slightly redesigned mantlet with a flattened and much thicker lower "chin" design started to be fitted to Panther Ausf G models, the chin being intended to prevent such deflections. Conversion to the "chin" design was gradual, and Panthers continued to be produced to the end of the war with the rounded gun mantlet.

In most cases the Panther's gun mantlet could not be penetrated by the M4s 75 mm gun, the T-34s 76.2 mm gun, or the T-34-85s 85 mm gun. But it could be penetrated by well-aimed shots at 100 m by the 76mm M1A1 gun used on certain models of the M4, at 500 m by the Soviet A-19 122 mm gun on the IS-2 and at over 2500 yards (2286 m) by the British Ordnance QF 17 pounder using APDS ammunition. The side turret armor of 45 mm (1.8 in) was vulnerable to penetration at long range by almost all Allied tank guns, including the M4's 75 mm gun which could penetrate it at 1,500 m (0.93 mi). These were the main reasons for continued work on a redesigned Panther turret, the Schmalturm.

The Ausf A model introduced a new cast armor commander's cupola, replacing the more difficult to manufacture forged cupola. It featured a steel hoop to which a third MG 34 or either the coaxial or the bow machine gun could be mounted for use in the anti-aircraft role, though it was rare for this to be used in actual combat situations.

The first Panthers (Ausf D) had a hydraulic motor that could traverse the turret at a maximum rate of one complete revolution in one minute, independent of engine speed. This slow speed was improved in the Ausf A model with a hydraulic traverse that varied with engine speed; one full turn taking 46 seconds at an engine speed of 1,000 rpm but only 15 seconds if the engine was running at 3,000 rpm. This arrangement was a slight weakness, as traversing the Panther's turret rapidly onto a target required close coordination between the gunner and driver who had to run the engine to maximum speed. By comparison, the turret of the M4 Sherman turret traversed at up to 360 degrees in 15 seconds and was independent of engine speed, which gave it an advantage over the Panther in close-quarters combat. As usual for tanks of the period, a hand traverse wheel was provided for the Panther gunner to make fine adjustment of his aim.

Further development

After the Panther II project died, a more limited upgrade of the Panther was planned, centered around a re-designed turret. The Ausf F variant was slated for production in April 1945, but the war ended these plans.

The earliest known redesign of the turret was dated November 7, 1943 and featured a narrow gun mantlet behind a 120 mm (4.7 in) thick turret front plate. Another design drawing by Rheinmettall dated March 1, 1944 reduced the width of the turret front even further; this was the Turm-Panther (Schmale Blende) (Panther with narrow gun mantlet).

Several experimental Schmalturm (literally: "narrow turret") were built in 1944 with modified versions of the 75 mm KwK 42 L/70, which were given the designation of KwK 44/1. A few were captured and shipped back to the U.S. and Britain. One is on display at the Bovington Tank Museum.

The Schmalturm had a much narrower front face of 120 mm (4.7 in) armor sloped at 20 degrees; side turret armor was increased to 60 mm (2.4 in) from 45 mm (1.8 in); roof turret armor increased to 40 mm (1.6 in) from 16 mm (0.63 in); and a bell shaped gun mantlet similar to that of the Tiger II was used. This increased armor protection also had a slight weight saving due to the overall smaller size of the turret.

The Panther Ausf F would have had the Schmalturm, with its better ballistic protection, and an extended front hull roof which was slightly thicker. The Ausf F's Schmalturm was to have a built-in stereoscopic rangefinder and lower weight than the original turrets. A number of Ausf F hulls were built at Daimler-Benz and Ruhrstahl-Hattingen steelworks; however there is no evidence that any completed Ausf F saw service before the end of the war.

Proposals to equip the Schmalturm with the 88mm KwK 43 L/71 were made from January through March 1945. These would have likely equipped future German tanks but none were built, as the war ended.

The Panther was the third most produced German armored fighting vehicle.

Historical Gallery

Sources and External Links

| Light Tanks | |

| Medium Tanks | |

| Heavy Tanks | |

| Tank Destroyers | |

| Self-Propelled Artillery |

| USA | |

| UK | |

| Germany | |

| USSR | |

| China | |

| Japan |